Air

Questions? Call (225) 715-5784

“Chattanooga, Tn Modad Septic Tank Aerators, Air Pumps, Blowers & Air Compressors?”

The words above are used interchangeably to describe the apparatus that provides air to the modad treatment plant. The most accurate term is “Air Pump”, and it’s function is to generate a constant flow of air to the modad aeration system by way of a 1/2″ pvc pipe that leads to the first chamber of the modad treatment plant. Inside this chamber, the pvc pipe is directed downward about 5.5 feet to within inches of the bottom of the tank and then branches out forming a tee with numerous drilled holes to allow the air from the air pump to diffuse through the liquid sewage from bottom to top much as an aquarium aerator does.

“Why Do Chattanooga, Tn Septic Tanks/Sewer Treatment plants Need Air Pumps And Aeration Systems When Septic Tanks Don’t?”

Most modern installations of commercial and residential waste water treatment plants (MODADS), in Chattanooga, Tn are required to use Aeration Systems and air pumps. So why is this requirement made? What is the advantage?

The reason and the advantage is that sewer treatment plants with an aeration system give an effluent of about 95% clean water, while the trusty septic tank, without aeration, discharges water that is only 45 to 65% clean. This is not to say that you should be hooking up your modad treatment plant discharge line to your potable water line anytime soon!!! But it is a very powerful outcome to what seems like a very simple add-on. Let’s go over the differences between how the septic tank and modad treatment plants (with aeration) break down sewage waste.

“The Septic Tank In Chattanooga, Tn Without An Air Pump and Aeration System”

The “septic tank” is a round cylinder or square tank that has only a single chamber. The septic tank utilizes naturally occurring anaerobic bacteria to breakdown the waste water. They are called “anaerobic” because they decompose sewage waste without air (oxygen). it should be no surprise that these same anaerobic bacteria are already at work in our digestive system well before coming to the septic tank! (what a lovely thought!)

The septic tank anaerobic process breaks down sewage through Hydrolysis (adding water), that sets off fermentation which first produces acetic acid, Hydrogen and carbon dioxide. This in turn gives rise to ammonia, methane gas and the inevitable rotten egg smelling hydrogen sulfide gas, that gives us such a fond attachment to the septic tank! Of course we too give off the same gases through the same processes. How does it feel to know that we are all little walking septic tanks??!!!

So if all this harmless gas is given off, surely the outcome must be a clean water discharge…far from it. Actually the anaerobic process water discharge is full of minute, still soluble (undigested) particles. Added to this acetic acid, ammonia and hydrogen sulfide gas all remain in the water. Such a mix, and with little or no oxygen. Can you imagine what large amounts of water like this would do to any organisms living in it…like fish for instance??!

Since those of us who live in Chattanooga, Tn and know what swamp land is like, we can now understand why the water in these areas can look brown and smell so bad. You guessed it…because all the organic matter sinks to the sludgy bottom and begins the anaerobic process of fermentation. The smell is that hydrogen sulfide gas. The color of the water is due to the acetic acid that leaches the tannin (brown) pigment from the plant material as it decomposes.

“The Waste Water Treatment Plant With An Air Pump and Aeration System”

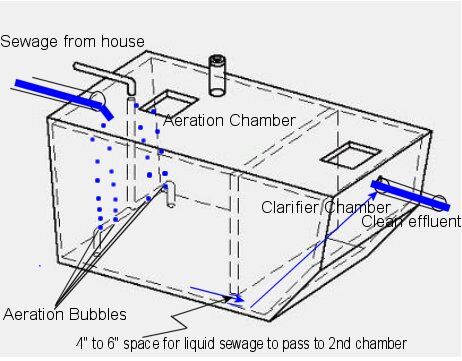

Most septic tanks in Chattanooga, Tn are now being replaced with the Modad waste water treatment plants with a modad air pump and Aeration System. The drawing below is the typical set up for these plants. As you can see in this example, the tank has two chambers (although some have three); the first is the Aeration Chamber, where air from the Modad air pump is directed to the bottom of the tank through a 1/2″ pvc pipe that tees off there and releases bubbles up through small holes drilled in the pipe.

The purpose of all this is to agitate and thoroughly aerate the incoming waste water. This allows the aerobic bacteria or bacteria that need oxygen to decompose and transform the waste water into something realtively clean to do their work.

Now let’s trace the path of the incoming sewage. As we have seen, it first enters the aeration chamber to be oxygenated. Before going further it is important to understand that the Modad Treatment plant, like the septic tank is an overflow system. This means that contrary to what most people think, the modad tank is always full! The inlet pipe you see coming into the tank from the house is set up about 4″ above the waste water level in the tank. The outlet pipe you see leaving the Modad by way of the clarification chamber is set 4″ lower than the inlet pipe from the house. This maintains a constant waste water level by way of an overflow. What this means is if, for instance, you flush a toilet, the 3 gallons going into the Aeration Chamber will have give rise to 3 gallons going out of the modad tank Clarifier Chamber overflow. So you see, the treatment plant is always full, but in a constant state of water moment as you input sewage water.

Now back to the waste water coming into the Aeration chamber. The organic solids, oils and greases in the sewage will be buoyant and remain on the surface until they are digested by aerobic bacteria. Then every time your waste water enters the Modad tank from the house, the digested waste water below the solid floating wastes are circulated down and out through the 4″ to 6″ space under the separation wall (Baffle) shown above and into the Clarifier Chamber. Remember, 3 gallons entering the Modad tank means 3 gallons going out the Clarifier chamber outlet pipe. The Clarifier Chamber is just that; In the intervals when sewage is not circulation into The Modad treatment plant the now digested waste water in the Clarifier Chamber settles out, in that any heavy particulates fall to the bottom leaving the clearer water on the surface to be pushed out upon the next waste water entering into the Modad from the house. Now what are the results?

If working according to design, this process will not give off methane, hydrogen sulfide (stinky gas) or acetic acids like the anaerobic bacteria of the septic tank, but rather carbon dioxide and minute particles of insoluble (already digested) solids, along with nitrates and sulfates. Best of all, the discharge water will leave the tank in an oxygenated state which will not be harmful to aquatic animals.

“In Chattanooga, Tn It Makes Sense To Have A Waste Water Treatment Plant And To Make Sure Your Air Pump, Aerator Is Working Properly”

We have seen from the results of the Waste Water Treatment Plant in Chattanooga, Tn that it makes good sense to ensure your Modad air pump, aerator is working properly. How do we do this and what are problems with Modad air pumps, aerators and blowers?

“What Types of Air Pumps-Aerators-blowers are there and what is the best Type of for your Modad Waste Water Treatment Plant?”

The oldest types of aeration devices are probably the “Mixer Aerator” and the “Rotary Blower” pictured below:

Rotary Blower Mixer Aerator

The Rotary Blower is an excellent aerator that puts out more air than any other type of aerator, but like the mixer aerator to the right, both have the disadvantage of having large electric motors that consume a lot of electricity and so are expensive to run 24 hours a day. For this reason, they are usually put on a timer to save on energy and run many on and off cycles during the day. This presents another problem of increased wear to the starter condenser of the electric motor and to the starter switch contact and failures of these are frequent.

If you still have one of these two types of aerators, it is probable that they are no longer working. Add to this the certified replacement aerators are often no longer available. Consequently, most of the Modad sewer treatment plant manufacturers have now certified the newest type of air pump aerator called the “Linear Diaphragm Air Pump” (shown below) for their respective treatment plants.

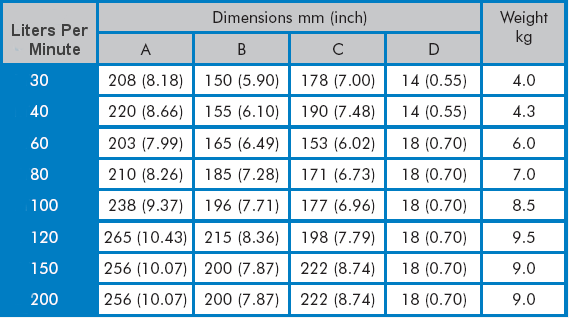

Linear Diaphragm Air Pump

The Linear Diaphragm Air Pump is much like the smaller vibrating aquarium air pump. It works as shown in the following animation. This is a very simple, efficient pump that usually works 24 hrs per day for 3 to 5 years without a problem. After this time the plastic diaphragms are worn and may be replaced with an inexpensive kit.

“The National Sanitation Foundation (NSF) And Certification of Aerator, Air Pumps For Modad Sewer Treatment Plants in Louisiana”

As we have seen, the Linear Diaphragm Air Pump is the best modern air pump for aeration in residential sewer treatment plants in Louisiana. However, the National Sanitation Foundation (NSF) is the governing body that certifies which size, make and model of air pump may be “legally” used for each make and model of Modad sewer treatment plant.

This is all to say that even though there are many compatible linear Diaphragm Air Pumps manufactured that give exactly the same volume and pressure as the NSF “Certified” Linear Diaphragm Air Pumps, only the “Certified” pumps are “Legal”. And “Legal” means, at least in Louisiana, that if you sell your house you must have the “Certified”, “Legal” air pump specified for your Modad Sewer Treatment Plant installed. (Please check for local laws and specifications for your respective State.)

Naturally, these certified linear diaphragm air pumps are more expensive than other compatible linear Diaphragm air pumps with exactly the same specifications. So, if you are not expecting to sell your house within five years or so, your selection of a more economical pump might be warranted. We do sell both certified and uncertified air pumps for this purpose.

OK, now that you know everything that you need to know about Aerators and Air Pumps, click here and take a look at the air pumps we offer:

“Septic Aerator Air Pump Store”